全国服务热线: 18036069041

National Service hotline: 18036069041

一、特点Characteristic

1.焊接时间短,超声波自动缝合免用针线,省去频繁换针线的麻烦,缝合速度是针车绗缝的5到10倍,宽幅由客户自定;

2.由于不用针,避免了缝合加工有断针残留在料内的情况,消除了安全隐患,属于新一代的安全环保产品;

3.没有传统线缝合的断线接头情况,粘固力强,压纹清晰,表面更加具有立体浮雕效果,产品更显高档美观;

4.加工后成品无针孔不渗水,更具防水保暧效果;

5.利用滚轮模具,换模容易,可缝合出千变万化且复杂的非连续性及对称性图案,更可依客户需求开发各种花形图案;

6.本机自动智能化程度高,装配红外线自动对边系统能自动修正各层物料,使缝合时上下物料始终保持对齐状态,加工损耗低,产品更加平整稳定。

1. The welding time is short, the ultrasonic automatic suture is free of needle and thread, saving the

trouble of frequent needle and thread change, the stitching speed is 5 to 10 times that of sewing car

quilting, and the width is determined by the customer;

2. Due to the lack of needles, it avoids the situation that broken needles remain in the material during

the stitching process, eliminates potential safety hazards, and belongs to a new generation of safe and

environmentally friendly products;

3. There is no broken thread joint with traditional thread stitching, strong cohesion, clear embossing,

more three-dimensional relief effect on the surface, and the product is more high-end and beautiful;

4. After processing, the finished product has no pinholes and no water seepage, which is more

waterproof and ambiguous;

5. Using roller mold, it is easy to change the mold, and can sew out the ever-changing and complex

discontinuity and symmetry patterns, and can develop various flower patterns according to customer

needs;

6. The machine has a high degree of automatic intelligence, and the assembly infrared automatic edge

alignment system can automatically correct the materials of each layer, so that the upper and lower

materials are always aligned during stitching, the processing loss is low, and the product is more flat

and stable.

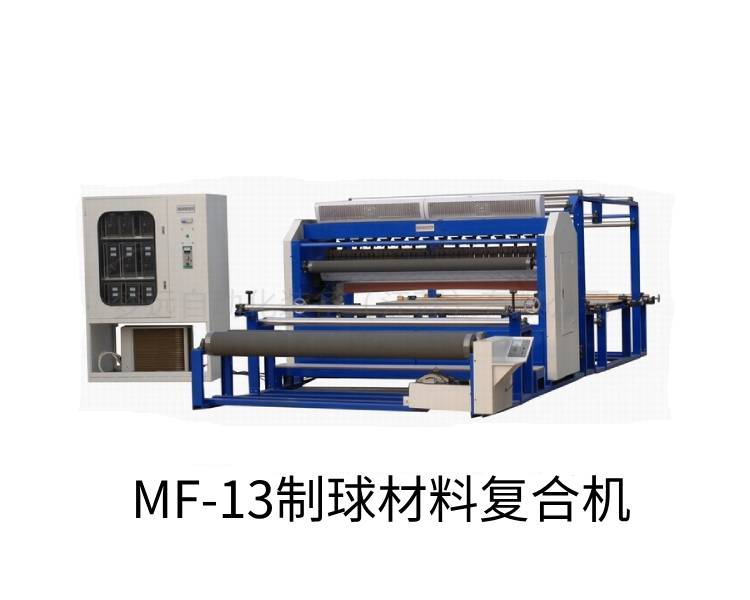

二、主要技术参数MainTechnica Parameter

| 外形尺寸 | 2000 (mm) | 品牌 | 蒙泰奇 |

| 包装 | 无 | 电源 | 380 |

| 放卷直径 | 客户自定 | 复合层数 | 客户自定 |

| 复合宽度 | 客户自定 | 类型 | 超声波复合机 |

| 收卷直径 | 客户自定 | 重量 | 2500 |

| 总功率 | 16 |